Explosion Protection Glossary of terms

Below is a glossary of terms and definitions for many of the terms and acronyms used in the subject of explosion protection and products for hazardous areas.

ATEX 1999/92/EC Directive

‘’Minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres’’.

Also referred to as ATEX 137 or the Workers Protection Directive.

ATEX 2014/34/EU Directive

‘’Equipment and protective systems intended for use in potentially explosive atmospheres’’.

Also referred to as ATEX 100a or the manufactures Directive.

Anti-Static

Has the property to not generate static electricity.

ATEX European Legislation

‘ATmospheres EXplosive’ split into 2 Directives.

Auto ignition temperature

This is the lowest temperature at which the vapour will be ignited. This defines the T class.

Category ATEX 2014/34/EU

Classifies equipment into three categories according to the level of protection employed:

- Category 1 – Very high level of protection

- Category 2 – High level of protection

- Category 3 – Normal level of protection

DoC Declaration of Conformity

Certification to demonstrate that Pyroban have taken full legal ownership of the equipment to allow a CE mark to be affixed.

DoI Declaration of Incorporation

Certificate to demonstrate that the equipment has been converted in accordance with the relevant requirements. This level of declaration needs to be incorporated into the manufactures certification to allow CE mark to be affixed.

DSEAR UK legislation

ATEX transposed into UK law. Dangerous Substances and Explosive Atmospheres Regulation. Complying with DSEAR in the UK is also complying with ATEX.

Electrically conductive

Has the property to conduct static electricity.

EN1755 European Standard

‘’Safety of Industrial trucks – Operation in potentially explosive atmospheres – Use in flammable gas, vapour, mist and dust.’’

Used as guidance on how to meet the requirements of the Directive 2014/34/EU.

EN1834 European Standard

‘’Reciprocating internal combustion engines – Safety requirements for design and construction of engines for use in potentially explosive atmospheres.’’

Used as guidance on how to meet the requirements of the Directive 2014/34/EU.

Flashpoint

This is the lowest temperature at which a liquid generates sufficient vapour to support ignition.

Gas group Ignition energy

All surface industry gases are classified as Group II gases. Group II is sub-divided into 3 sub-groups:

- IIA – High energy is required to ignite. Less intense explosion.

- IIB – Less energy is required to ignite. More intense explosion.

- IIC – Little energy is required to ignite. Most intense explosion.

- Hazardous Area

An area in which an explosive atmosphere is present or may be expected to be present. This sign informs you that you are entering a hazardous area.

An area in which an explosive atmosphere is present or may be expected to be present. This sign informs you that you are entering a hazardous area.

Ignition Triangle

Diagram to demonstrate the 3 ingredients that must be present to produce an explosion: Fuel + Air + Ignition Source.

IP Ingress Protection

Industry code to demonstrate the level of protection achieved against ingress of solids and liquids.

Non-Hazardous Area

An area in which an explosive atmosphere is not expected to be present.

Risk assessed

On category 3 vehicles some items are risk assessed. This means they have been examined by Pyroban against the essential health and safety requirements defined under ATEX and associated standards.

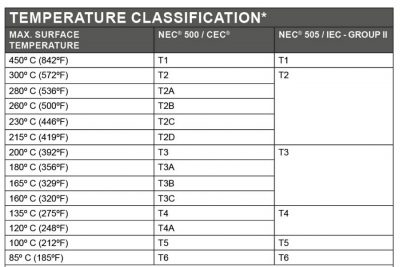

T class Temperature class

The temperature at which ignition will occur through contact with a hot surface. Represented as a T number from T1 – T6.

- T class T1 < (Max. Surface Temp.°C) 450°C

- T class T2 < 300°C

- T class T3 < 200°C

- T class T4 < 135°C

- T class T5 < 100°C

- T class T6 < 85°C

Zone

ATEX 99/92/EC classifies areas that may be at risk of having an explosive atmosphere:

- Zone 0 – Gas is continuously present or present for long periods.

- Zone 1 – Gas is likely to occur in normal operation.

- Zone 2 – Gas is not likely to occur in normal operation and, if it does occur, is likely to

do so.

Zone 20, Zone 21 and Zone 22 are similar definition as above but the hazard is from dusts and powders as above but the hazard is from dusts and powders in place of gas.

For more information or to speak to Pyroban explosion protection specialists contact us.

DIESEL ENGINE EXPLOSION PROTECTION FOR ZONE 2 HAZARDOUS AREAS

Diesel engines are used in Zone 2 hazardous areas offshore to power temporary well service equipment such as Coiled Tubing Units, cementing units, air compressors and much more. Pyroban provides explosion protection solutions including:

- Explosion protection (ATEX) engine Kits – for multiple engine types used in well service equipment

- Explosion protection (ATEX) engine Packages – from leading OEMs for use in well service equipment

EXPLOSION PROTECTION COMPONENTS

Pyroban manufactures a wide range of explosion proof (ATEX) components certified for use in hazardous areas.

- Ex Alternator (power)

- Ex Alternator (battery charging)

- Ex battery

- Super Insulated Pipes

- Shut-off Valves

- Spark arrestors

- Ex SCS

- PCS2

- Ex Starter motors

EXPLOSION PROTECTION FOR LIFT TRUCKS IN HAZARDOUS AREAS

We offer explosion protection conversions for lift trucks, reach trucks, pallet and stacker trucks, VNA and pickers. Conversions take place at Pyroban in the UK.

- Zone 1 – ATEX 2G conversions

- Zone 2 – ATEX 3G conversions with Gas detection (system6000)

- Zone 2 – ATEX 3G conversions without Gas detection

- Zone 21 – ATEX 2D conversions

- Zone 22 – ATEX 3D conversions

EXPLOSION PROTECTION FOR CRANES, ACCESS PLATFORMS, SCRUBBER DRIERS…

For Cherry Pickers, scissor lifts, cranes, access platforms, scrubber driers, tractors and more, Pyroban provides ATEX compliant conversions for use in Zone 1, 2, 21 and 22.

OTHER EXPLOSION PROTECTION SOLUTIONS

Pyroban’s new explosion protection services, EXSolutions, supports OEM and end-user businesses on their journey to ATEX, UKEX and IECEx compliance. Services include:

- Ignition Hazard Assessments (IHA), inspections, audits, and practical Ex engineering solutions for all types of equipment.

- Ex telemetry. Unique sensors to improve preventative maintenance of electro-mechanical equipment and lighting systems.

- EX electrical and mechanical system design, EX enclosure population, EX product development and certification support for OEMs. Find out more

- Ex lighting design and installation services providing energy efficient LED lighting solutions.

- Advanced fire suppression systems for a range of mobile and fixed equipment applications (not Ex).