Explosion proof lighting design and installation (ATEX / IECEx / DSEAR)

EXSolutions provides detailed lighting design and installation services that are engineered for use in hazardous areas.

With deep understanding of explosion proof lighting and equipment, we ensure ATEX / IECEx / DSEAR compliance, energy efficiency, low maintenance and high levels of performance to optimise lifetime operating costs. And we make sure that there are the right levels of light where safety is paramount.

Our Ex lighting solutions typically feature Petrel lighting and are suitable for a wide range of applications including onshore and offshore processing, manufacturing, storage and many other hazardous area applications such as distilleries, utilities, chemicals, food or pharmaceutical.

Service delivered by Pyroban’s EXSolutions team:

New installations or replacement explosion proof lighting in DSEAR / ATEX areas

EXSolutions’ installation services by CompEx engineers support businesses creating new facilities, or those with existing applications where the lighting may be failing, old and inefficient, or simply not bright enough.

Often, an upgrade to ATEX compliant LED technology brings significant improvements in both performance and energy saving.

Our goal is to deliver the optimum functional performance for the explosion proof lighting system with due consideration for the activities taking place in each hazardous area. This includes work patterns, areas where shadows may occur, and the levels and type of light required in specific areas to enhance the working environment for operators and staff.

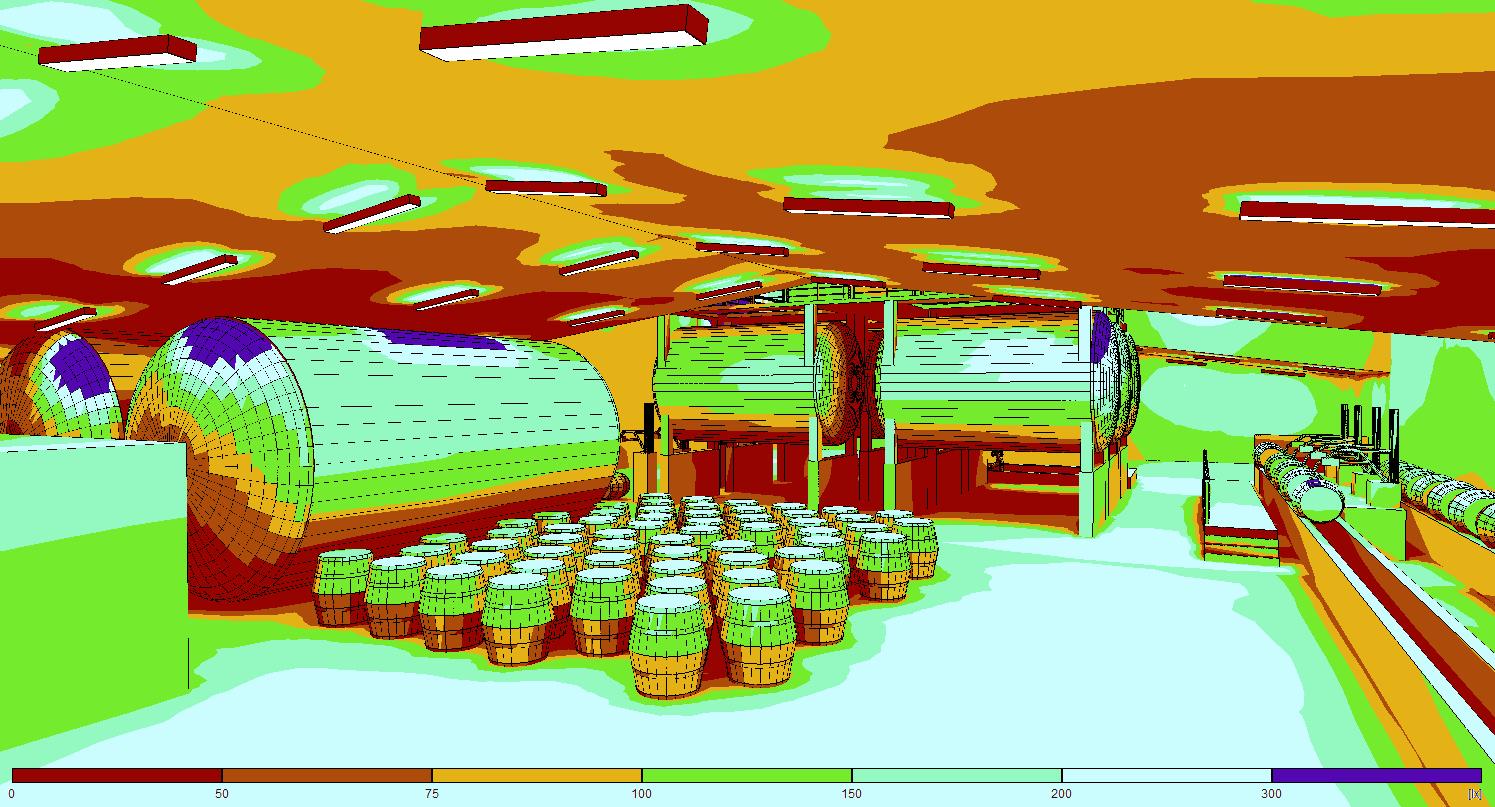

Explosion proof lighting design process

We first define the overall lighting requirements for each Zoned area following a thorough understanding of the activities being undertaken in the areas to be considered. A site survey may be conducted to facilitate this, enabling the generation of new and accurate drawings or the modification of existing ones. This is followed by a detailed mapping of each area to define exactly what explosion proof lighting is needed.

The fully integrated designs will define the specification of all the lighting to meet Zone and environmental requirements. It will show where junction and terminal boxes may be located and detail the required cable glands or ancillary products. We select the most appropriate lighting products for the application or can work with our customer’s preferred brand where required.

The lighting scheme is completed by experts who have many years’ experience in lighting designs, not only for hazardous area applications, but also lighting schemes for standard industrial operations across a wide range of sites and applications no matter how large or small.

Customers are invited to review all aspects of the proposed lighting scheme in each area, following which a commercial proposal is provided for approval prior to the commencement of any installation work.

Ex lighting installation (ATEX / UKEX) process

Once a commercial proposal for supply and installation is accepted, our design team will remain available for the duration of the project to advise on final fitting positions and assist with any design alterations that may be required.

Installation is performed by CompEx accredited engineers with many years of experience in hazardous areas to ensure compliance.

EXSolutions will coordinate the design, specification, procurement, delivery and installation of the explosion proof lighting products, glands, cables, junction boxes, and any other ancillary equipment to ensure that the complete lighting installation runs smoothly.

Full documentation is provided to support the ongoing maintenance and compliance of the lighting installation.

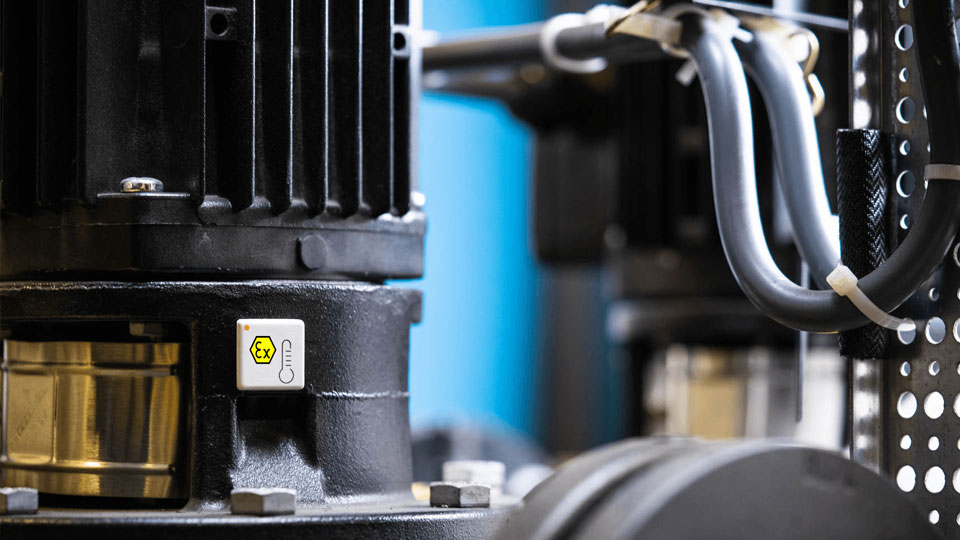

Ex maintenance and Smart Sensors

As industry gets smarter, the opportunities that digitisation and the Industrial Internet of Things (IIoT) / Industry 4.0 can bring to hazardous area operations are exciting.

Such systems can reduce maintenance costs, facilitate Environmental, Social and Governance (ESG) agendas and enable businesses to work smarter and even more safely in hard to access, high risk, or un-manned manufacturing and process areas.

In these ATEX areas, we can add Ex sensors to the lighting system to help reduce maintenance requirements and identify any potential problems before they happen. We can help detect moisture, temperature, water or humidity for example, helping to pinpoint maintenance needs before they initiate a potential failure, thus reducing costly downtime.

EXSolutions can bring IIoT(Ex) to your hazardous area and provide solutions for the remote maintenance and management of not just the lighting system, but a wide variety of electro-mechanical devices.

Contact our Business Development Consultants for an initial discussion.

Petrel – our preferred lighting partner

Petrel has been our preferred explosion proof lighting partner for many years due to the product range, design and quality. In 2024, Petrel joined the Pioneer Safety Group alongside the EXSolutions brand bringing even greater benefits to customers.

Find out more about Petrel’s hazardous area lighting.

Phasing out of fluorescent and Halogen lighting

With the transition away from fluorescent and halogen lamps the advent of LED is here. We are fully equipped to meet your transition needs. These replacement bulbs are no longer in manufacture, so a proactive plan for transition either in one go or to replace as necessary as an ongoing project, beside the annual inspections of Ex lighting is what we can help you with. Read more.