Ex Telemetry and Sensors

Industry is getting smarter, and EXSolutions is helping hazardous area operations digitise and benefit from the Industrial Internet of Things (IIoT) to improve operational and maintenance effectiveness. EXSolutions’ Ex IIoT solutions provide remote monitoring of electrical and mechanical equipment through unique EX sensors which provide critical “heartbeat” information to identify issues before they could lead to equipment failure.

It will enable businesses to work smarter and even more safely in hard to access, high risk, or un-manned manufacturing and process areas.

In addition to supporting regulatory compliance of EN60079-17, the sensors can help reduce process downtime, reduce maintenance costs, and the improved effectiveness facilitates Environmental, Social and Governance (ESG) agendas.

Service delivered by Pyroban’s EXSolutions team:

SMART Microsensors = SMART Maintenance

Hazardous area operations are highly demanding industrial environments in which explosion proof equipment may operate 24/7 and be subjected to operational stresses and other environmental factors. Preventative maintenance programs aim to minimise the risk of downtime through proactive monitoring of the equipment. Equipment failure can occur as a result of factors not detected by traditional techniques or inspection intervals.

Our smart microsensors allow critical aspects such as temperature, humidity, water presence and door open/closed to be monitored as a heartbeat for each piece of equipment, available through a secure internet connection.

Alerts can be configured to send emails to inform maintenance teams if equipment parameters go out of range.

The door open/closed sensor provides invaluable information that an enclosure may not be fully closed following a service or maintenance intervention and is therefore vulnerable to environmental ingress, an issue not normally detected by conventional methods.

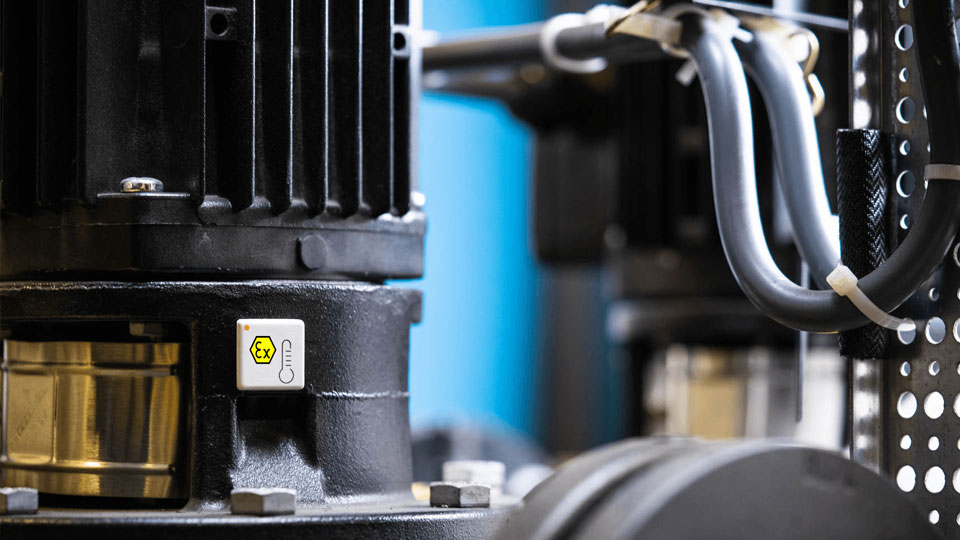

EXSolutions Ex telemetry and smart ATEX microsensors

The smart sensors operate independently of any existing process control sensors, do not require a hard wire connection, have internal battery capacity for 5 years use, and are incredibly small (just 19mm) and easy to affix to the equipment.

To provide a comprehensive timeline, touch sensors can be used to record someone has attended an area or a piece of equipment as part of a maintenance routine.

The sensors are ATEX / UKEX / IECEx certified intrinsically safe for use in zone 0,1, 2, and zone 20, 21, 22 areas.

These sensors and the acquired information presented in the dashboard allow maintenance programs to be more effective; using quantitative data to help:

- Assess inspection intervals,

- Plan timely regulatory EN60079-17 inspection and maintenance deployments,

- Trigger urgent interventions to minimise equipment failure risks,

- Provide evidence into the facility DSEAR / ATEX records.