Hazpak™ 100 – ATEX Engines for Zone 2

Explosion Proof Packages

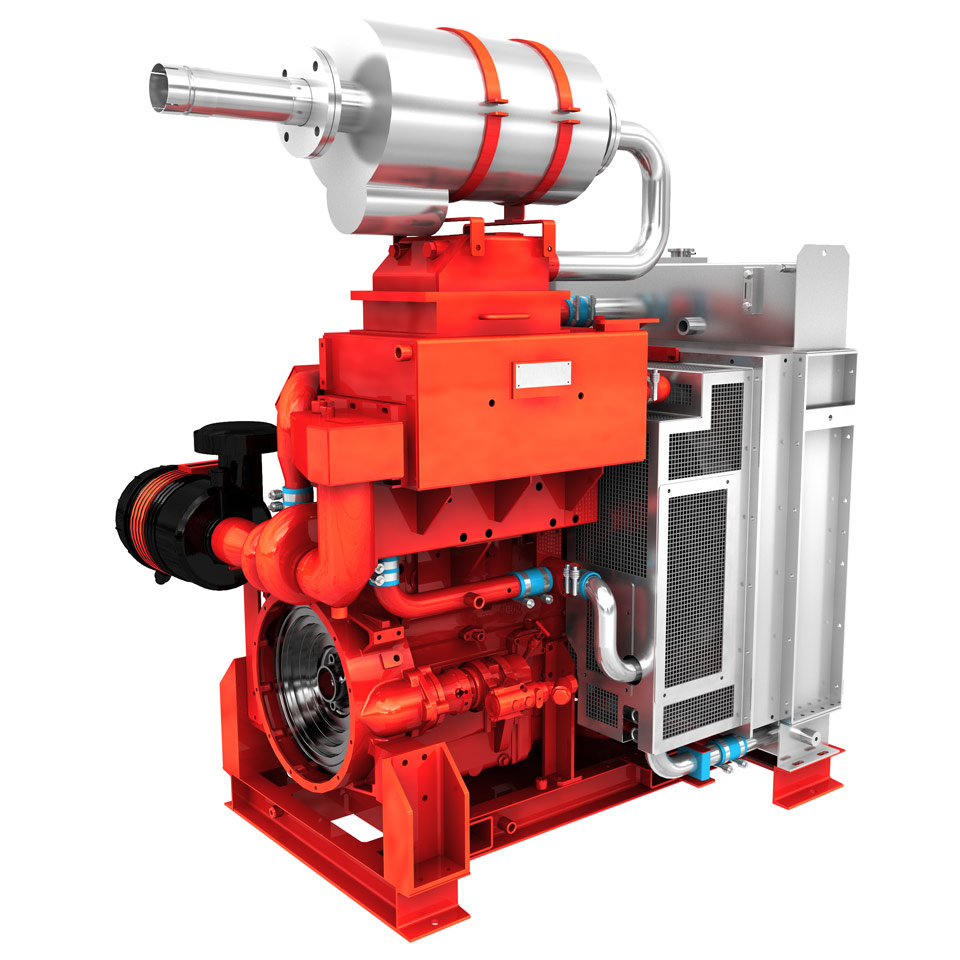

Pyroban HazPak™ 100 – >100 bhp ATEX engines are Radiator to flywheel, Ex-certified packaged engines.

The most popular brands are Cat, JCB and Perkins, but we can also convert most other brands. When you specify a Pyroban Hazpak™ you’re buying a pre-engineered and certified solution suitable for Zone 2 hazardous areas.

Pyroban have conducted all necessary engineering, testing and final certification, including all Flame non-transmission testing and thermal testing in our Dyno facility. We can produce standard packages that comply with EN1834-1:2000, but also have the flexibility to address problems using ATEX 2014/34/EU and EN1127 and complete customised packages for IECEx, NORSOK Z-15 and DNV 2.7-2 Applications.

Fixed and Variable speed options are available. Depending on the specification of the donor engine. Donor engines can be free issued, or Pyroban can supply as part of the package.

See also Diesel Generator packages.

ATEX engines built for Zone 2 hazardous areas

With in-house test facility procedures and approval to International standards, Pyroban ensures quality at every step in the process. We offer the following explosion proof engines in this power rating and more:

- Pyroban C4.4 NA

- Pyroban C4.4TA

- HazGen

- Perkins 1100

Typical explosion protection features include:

Typical explosion protection features include:

- Air inlet shut-off Valve

- Air inlet flame arrestor

- Water-cooled Turbocharger & Exhaust Manifold

- Exhaust Gas Heat Exchanger

- Thermal control & treatment

- Exhaust Flame arrestor

- Certified spark arrestor

Additional components are added according to the application. See control systems and accessories tab.

Specification

The typical Pyroban Hazpak is suitable for use in hazardous areas where explosive gases occur (ATEX directive 2014/34/EU). The package provides protection to:

- Equipment Group: II

- Category: 3G

- Gas Group: IIA

- Temperature Class: T3

Conformance to the Temperature Class is dependent on ambient operating temperatures. For ambient operating temperatures above 45°C consult your customer services representative. ATEX-designed and tested exhaust system, compliant to EN 1834-1. Consult specific engine documentation for full details of what is included.

DATA SHEETS

- Pyroban HazPak 100 NA fixed – 2024

- Pyroban HazPak 100 NA variable – 2024

- Pyroban HazPak 100 TA fixed -2024

- Pyroban HazPak 100 TA variable – 2024

- HazGen

- Perkins 1100

MANUALS

CERTIFICATES

Support through the lifecycle

We understand that our customers need maximum up time and that the harsh locations they operate in may mean special training or certification is required. We Support our customers throughout the lifecycle of the equipment with a highly experienced and qualified team of Service technicians.

Control systems and accessories

Explosion protection kits can also include: