Two new Pyroban® 3406 HazPaks have recently been shipped featuring Pyroban’s unique Soft Compound Thermal Barrier (SCTB) and Ever Clear™, the long life exhaust flame arrestor. Once deployed, the operators do not have to clean the exhaust flame arrestor on a daily basis reducing operational downtime.

The two new 490hp ATEX powerpacks will be used by a large service provider in the USA in support of offshore well service operations and are built in accordance with ATEX 2014/34/EU and all necessary standards including EN1834-1:2000.

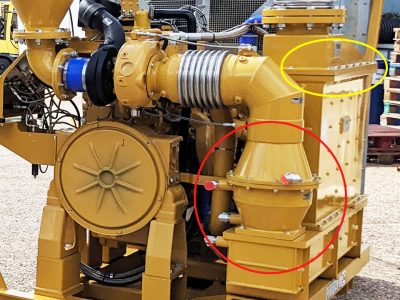

Each Pyroban 3406 HazPak™ is equipped with an Ever Clear™ exhaust flame arrestor (circled in red) which offers many benefits to operators, including reduced maintenance costs, increased personnel safety and reduced operational downtime.

How Ever Clear reduces operational downtime

Ever Clear exhaust flame arrestors act as a direct replacement for the traditional “plate type” flame arrestors often found in Pyroban explosion protected diesel engines.

Ever Clear exhaust flame arrestors allow the engine exhaust gases to pass through without clogging, but will stop a flame in the event of an exhaust backfire caused by hydrocarbon gas ingestion.

In the picture above, note the absence of the plate type exhaust flame arrestors (circled in yellow) which can otherwise present manual handling issues. Any concerns about “dummies” wrongly used in their place are also eliminated with Ever Clear.

The two new Pyroban 3406 HazPaks also include Pyroban’s unique SCTB (Soft Compound Thermal Barrier), the black coating seen here on the turbo and the charge air system.

The Soft Compound Thermal Barrier ensures the engines’ charge air system components remain below temperature class T3 (200degC) at high load in a 45degC ambient environment as required in this well service application.

Why the correct thermal control of ATEX engines matters

Our approach to thermal control is one of the many details that sets Pyroban apart.

One key area to look out for is the charge air system and compressor side of the turbo which reaches the 200degC (T3) temperature boundary very quickly in relatively low European ambient temperatures.

Pyroban is one of the only manufacturers that provides this level of thermal control with its SCTB (Soft Compound Thermal Barrier) coating technology to reduce the thermal signature.

Our commitment to safety in hazardous areas is paramount, which is why we won’t leave hot surfaces that could cause an ignition exposed.

The two 3406 ATEX units also feature an air inlet shut-off valve, air inlet flame arrestor, water-cooled turbocharger and exhaust manifold, exhaust gas heat exchanger, thermal control and treatment and ATEX certified spark arrestor.

Pyroban offers a range of radiator to flywheel HazPak™ ATEX engines, which provide up to 1100 bhp. They are fully Ex-certified packaged engines, Equipment Group II, Category 3G, Gas Group IIA and Temperature Class T3.

Pyroban HazPaks are designed for harsh offshore environments, produced to specification and receive great support in the field.

For more information contact our technical sales team on +44 (0) 1273 456800 or info@pyroban.com.