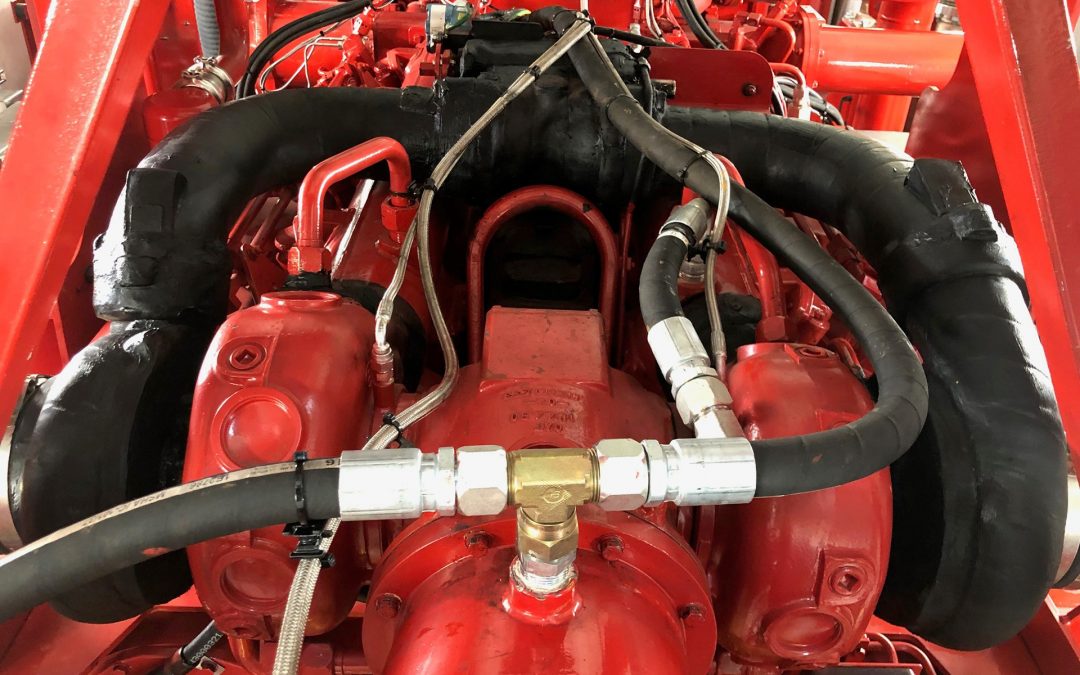

Pyroban recently completed works on applying a Soft Compound Thermal Barrier to two CAT 3508 ATEX diesel engines rated at 765kW on site, in record time.

Thermal signature is a critical factor to consider when making a diesel engine explosion proof for offshore hazardous area operation. There are many sources in a modern IC engine, and important areas to look out for include the charge air system and compressor side of the turbo which can reach beyond 200degC (T3 temperature class).

Pyroban ensures the correct level of thermal control that’s fit for purpose with its patented SCTB (Soft Compound Thermal Barrier) coating technology to reduce the thermal signature.

Two ATEX engines for a sea water deluge fire pump

The two new CAT 3508 ATEX engines have been fitted with a complete Pyroban explosion protection kit by a customer packaging a sea water deluge fire pump for a new oil platform operating in Africa.

As part of this conversion, the Pyroban SCTB thermal barrier was needed because the charge air temperature (from the turbo charger compressor outlet) and the corresponding inlet pipes would otherwise exceed 200degC T3 in the high operating ambient temperature. It was an essential modification for compliance with ATEX.

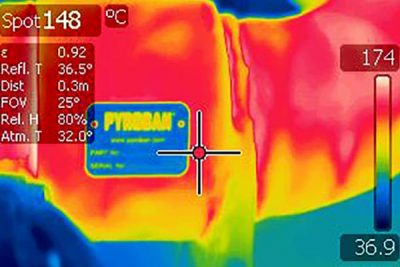

Thermal imaging was used to establish the thermal coating boundary and identify which parts need to be treated using the SCTB. The materials are hand applied to the OEM parts in layers to achieve the target temperature reduction. The material is proven fit for purpose in tough offshore applications, it is resistant to oils, diesel and salt spray, and its surface is anti-static.

Pyroban was the first company to introduce SCTB and the Hard Compound Thermal Barrier (HCTB) to address engine inlet and exhaust systems where the surface temperature exceeds the T class (in operating conditions) and where water cooled alternatives are not available or viable.

IMAGE: Here’s an example of a Pyroban protected Caterpillar engine at load showing a spot surface temperature of 148decC in a 32decC ambient atmosphere – proving that it is safe.

The key to the use of such solutions is the thermal imaging and analysis to ensure the extent of the coating is appropriate. Pyroban undertook significant research into the applications for both SCTB and HCTB and has more than a decade of experience in applying Pyroban patented SCTB solutions.

Technical and engineering support beyond normal

The customer had a very tight deadline to ensure the package shipped on time and requested Pyroban Service Engineers to complete the SCTB installation between testing phases.

Pyroban Engineer Steve Keeley worked extended days to install the first unit while a second engineer Martyn Ballinger even shortened his holiday and worked the weekend to complete the second unit to meet the customer’s deadline for testing.

Steve Noakes, Managing Director of Pyroban commented: “This project demonstrates Pyroban’s commitment to going the extra mile in aligning and supporting our customers to help them meet their deadlines and customer demands.”

Pyroban’s commitment to safety in hazardous areas is paramount, which is why we won’t leave hot surfaces that could cause an ignition exposed. We have been applying thermal coatings to the inlet systems of ATEX diesel engines since 2009 and have built up unrivalled knowledge of the process.

For more information contact our technical sales team on +44 (0) 1273 456800 or info@pyroban.com.