Pyroban® has announced that from 4th January 2022, forklift service engineers will be able to complete Pyroban refresher training courses online. The move is expected to significantly impact forklift OEMs and dealers who manage explosion proof forklift fleets, saving time and costs.

REGISTER FOR ONLINE REFRESHER TRAINING NOW“It is essential for the safety of hazardous area operations that the OEM and dealer service engineers are properly trained to maintain Pyroban equipment safely,” says Victoria Knight, Materials Handling Service Manager for safety company Pyroban. “That is why we still expect engineers with no experience of Pyroban systems to attend an initial two-day theory and practical course in person.”

In the past, after the initial training, a Pyroban trained engineer was advised to return after two years for a further on-site two-day refresher training course. However, the new online Pyroban course gives the customer the choice of preferred training method..

“The aim is to cut down on road miles, reduce hotel costs, and minimise the time our customers’ engineers have to spend on training, but without any compromise on safety,” says Victoria. “The interactive eLearning is suitable for customers all over the world and we hope that anyone who has been trained by Pyroban will make use of this new great value training option.”

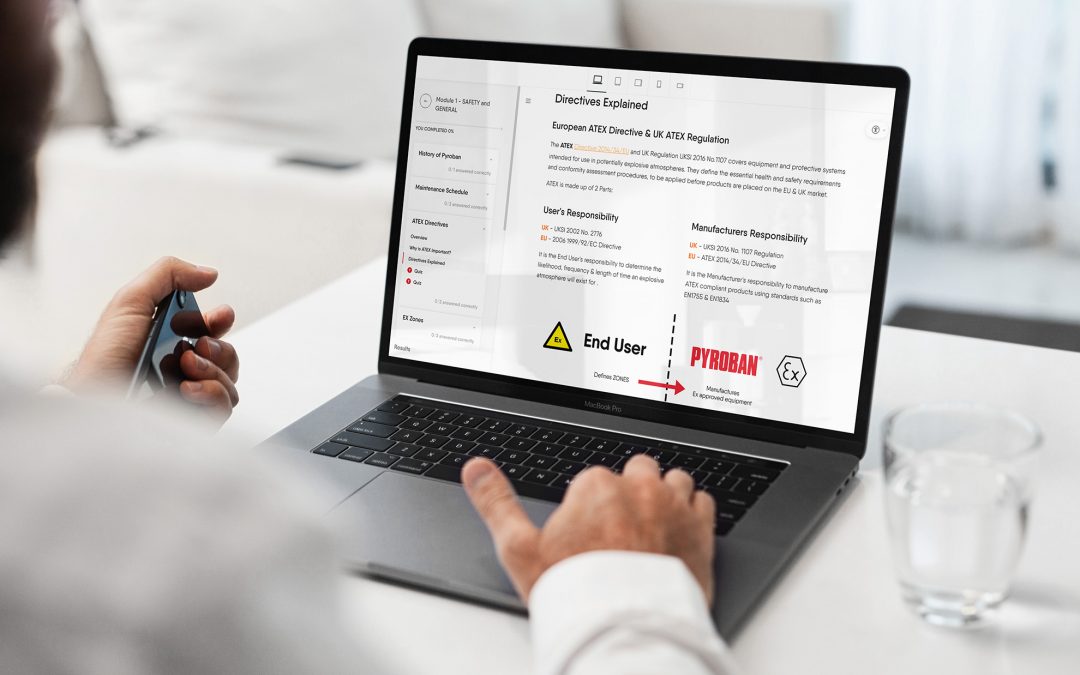

The new Pyroban eLearning course is divided into 5 sections. The first is a general hazardous area safety and ATEX course which must be completed by all refresher trainees. The candidates can then choose which topics to explore further, depending on what type of equipment they have in their fleet. The choices include electric equipment for Zone 1, or diesel equivalent, and then gas detection for either diesel or electric equipment in Zone 2. Dust is also covered in the relevant modules.

Course users receive an individual login with each section, which includes theory based learning followed by questions, and takes around one hour to complete. The eLearning system is easy to use, highly engaging, visual, and aimed at those engineers who are experienced in working with Pyroban systems.

“The course is not designed to just cover the same old ground, it re-establishes the correct way of doing things and acts as a reminder as to why doing the job properly is critical,” says Victoria, explaining that Pyroban converts forklifts so that they can be safely used in high-risk areas where a simple spark or heat source could potentially cause a highly destructive and fatal explosion.

The ATEX Directive requires the end user to “demonstrate that work equipment is designed and maintained with due regard for safety.” It calls for all equipment to be maintained in accordance with EN60079-17:2014. By ensuring that refresher training takes place, forklift OEMs and dealers are complying with health and safety laws and ATEX and minimising legal exposure in case of an incident.

“There are no short cuts when it comes to maintaining or repairing an explosion proof forklift. It is either safe or it is not and end users rely on the trained service engineer to use the correct parts and follow the correct procedures,” says Victoria. “We found, due to the pandemic restrictions, that some engineers could not attend a refresher course, so we wanted to make it as easy as possible for them to top up their knowledge and support continued safety in the field.”

Even prior to the pandemic, eLearning has become an increasingly useful tool for businesses including forklift operators, and Pyroban has undertaken many trials with customers to ensure the technology works effectively. Pyroban’s interactive eLearning courses are far more than a PowerPoint slide pack accessed remotely. They have been written from scratch specifically for effective eLearning.

“The eLearning method gives a time saving of almost two days per person which will make a huge difference for critical MHE service engineering teams that are extremely busy,” says Victoria. “In many cases, engineers can even do the course at the end of their working day or even out of hours at a time that suits them. Every course result is checked by Pyroban before the certificate is issued to identify any areas where further support or clarity may be needed. The attendee can also call into our Technical Support team if they have questions during the course giving the same level of support as the on-site courses.”

Pyroban will continue to offer a range of face-to-face training courses on-site or through webinars designed to help works and maintenance engineers, field service engineers, and service managers maintain Pyroban equipment in the field. Initial Pyroban training courses are held all year round for groups of 6 delegates (4 during Covid-19) in the UK in Cannock, West Midlands and Shoreham by Sea, West Sussex, France, Spain, the Netherlands, Germany and in many other countries.

Register your interest in Pyroban training by emailing training@pyroban.com or phone +44 (0) 1273 456824 to find out more.