New forklift sales people are often unsure of what to do when asked to quote for an explosion protected version of a forklift. This article from Darren Boiling aims to demonstrate that the Pyroban quoting process is actually very simple, and we are available every step of the way to help.

Quoting a Pyroban conversion for a forklift truck has never been easier and is now just a four step process on one single A4 page.

Salespeople can complete the fields in our “Request for Quote” pdf form and send it back to us, or print it and complete by hand, or we can do it over the phone or come to site. It really is simple and we can then provide a price for an ATEX forklift truck conversion.

So how much is an ATEX / explosion protection conversion? You will need to know a few facts first before we can quote.

It starts with the basics including date and contact details. We also request end user details at this stage if available as it gives us an idea of the site the equipment will work on.

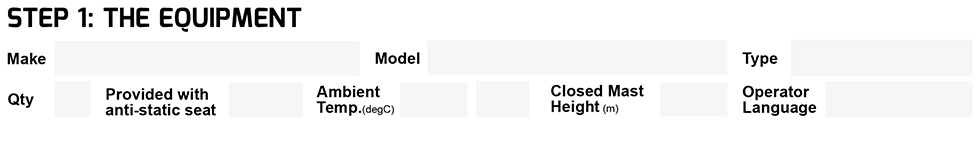

Step 1: Equipment Details

You should already know the details of the equipment that needs to be converted, such as a 2.5 tonne forklift truck. We require the full make and model identification, the type of equipment and quantity. As our solutions often need an anti-static seat, we need to know if one is being sourced/provided by you or if we need to quote.

The ambient temperature is also important particularly for equipment in North Africa or the Middle East for example. We may reduce surface temperatures, as part of our protection methods, which can have an effect on the equipment’s work cycle, especially if it is working in a high ambient. If we are aware of this requirement we can make changes to the solution that we offer so that this does not happen.

What may seem a small variation could have implications on the solution that we offer. Knowing the language requirements ensures we provide the correct labelling and instruction documents and that we are able to comply with import and export requirements.

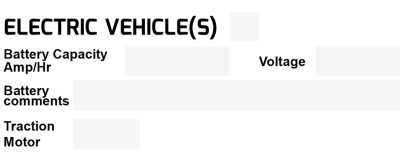

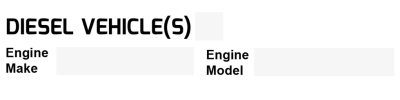

We then need to know the details for the relevant power type.

For electric vehicles, the battery details allow us to provide pricing for a certified battery should it be required. The battery compartment dimensions will allow us to order the correct battery for your truck well in advance which can impact on our build times. Alternatively you may wish to provide your own certified battery.

For diesel equipment, the continuing changes in engine technology means we require the full engine make and model accompanied by a spec. sheet if available.

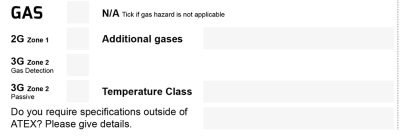

Step 2: The Hazard

Our quotation will be based on the specification of the area where the explosion protected forklift truck will be working. The end user is obliged by law to know this information and should easily be able to provide the details.

If this information is not known please contact the Pyroban sales team on +44 (0) 1273 456800 who can advise the best course of action, which may involve a visit to site.

For gas/vapour hazards, the solutions we offer are for either Zone 1 or Zone 2. Zone 2 protection can mean either our passive option (Ex-tec 3G™) or our Gas Detection option (system6000™). The end user will tell you what area(s) the equipment will operate in.

All solutions will comply with IIB gas groups as standard, which will cover the majority of applications. This relates to the auto ignition temperature of the hazard we are protecting against (such as solvents). Once again, the end user will tell you what this should be and there is an option to add the IIC gases hydrogen and/or acetylene if needed.

The only other piece of information we require for gas hazards is the T class which the end user can also give you. T4 is the higher requirement and is the default for our electric conversions. For diesel it is so important to know the correct T Class because T4 requires a higher level of engineering and test which will involve more cost. If you are unsure please call our sales team.

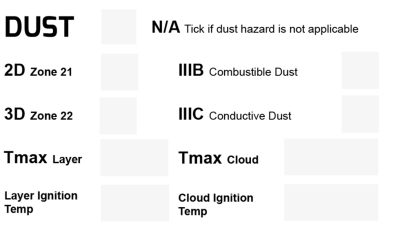

Dust hazards on the other hand require a bit more information which reflects the complexities of protecting against dust. This includes layer and cloud information which the end user should be able to provide.

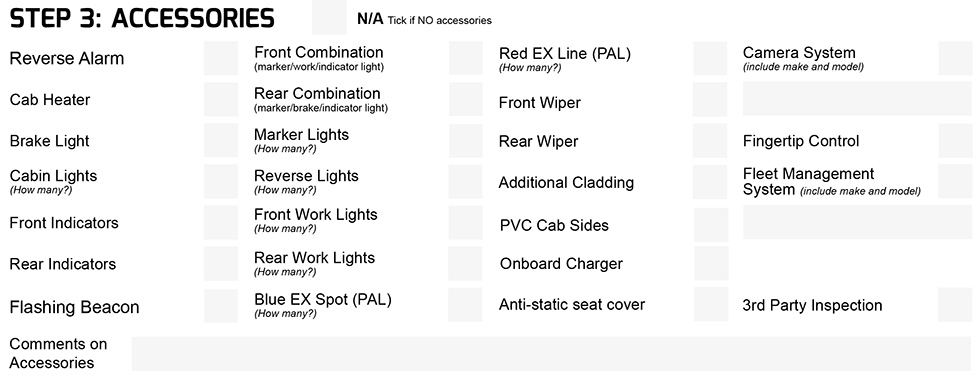

Step 3: Accessory Requirements

We will always recommend that accessories are kept to a minimum but where they are necessary we need as much information as possible about the accessories required. This is a simple tick list.

If a required option is not listed, simply add the details into the ‘Comments on Accessories’ field. Note that accessories must be fitted to the truck when we receive it for the conversion work unless agreed beforehand and if we are unable to make use of the OEM component we will replace with our own and return the part removed.

And remember, if a cab is fitted to the truck then options for wipers, cab heaters etc will have to be selected. Some other conditions apply and our team is happy to discuss various options.

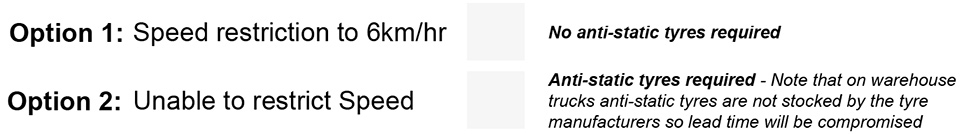

Step 4: Tyres

To comply with the European Standard EN1755: 2015 and ATEX 2014/34/EU the converted machine needs to be fitted with anti-stactic tyres (if the vehicle speed is above 6km/h). Here, there are only two options.

And finally, any relevant information that is not covered in the questionnaire should be detailed in supporting documentation or on email for inclusion into the quotation.

That’s it! The Pyroban team can then work on developing a quotation and a price for the explosion proof / ATEX forklift truck. This usually takes 3-5 days for equipment that we have seen before (or similar), but can take longer for high capacity machines, AGVs or equipment such as cranes or scrubber driers.

We understand that the complexities of explosion protection and all the legal implications are difficult to understand and can be overwhelming for professionals who are not in the explosion protection industry. Our aim is to make the quoting process as easy as possible for new people in the industry and for dealers looking to win business in operations with hazardous areas.

For more information and support with a quotation, contact Pyroban’s technical sales team on +44 (0) 1273 456800 or info@pyroban.com.